I’d love for Polyend to implement something like this. If you’d like to vote for the possible consideration of the inclusion of a MIDI keyboard or pads to the Tracker Mini, please chime in here: Built-in MIDI keys/pads for the Tracker Mini

Great idea and design👌

Now… if there was a tiny (even crappy) speaker included somewhere would be even greater ![]()

Well, it’s interesting that you mention this =_(ツ) … I’ve been thinking of a way to add some speakers as well. I think with a tiny amplifier chip, I can add a couple tiny speakers.

These are quite small. Think cellphone or tablet size.

This project is still evolving - working on software right now.

Looks amazing!

It will do the trick. The point of this speaker can not be mixing. The idea is to be able to chill on a couch or in a park and sketch out some ideas while being able to listen to your surroundings as well.

Can I ask how long it might take to develop and what the price range might be??

I’m looking to buy ![]()

![]()

So far, to get short-run (<10k units) injection molding tooling for this appears to be in the $10-15k range, depending on if we can get the buttons off-the-shelf. There would have to be a lot of support to consider a full commercial production run…

However, a “3D print yourself” or “buy a pre-made 3D printed case” version seems quite feasible…

looks amazin. love the speakers too ![]()

I’m not sure how to answer this just yet.

Once we get the hardware and software debugged, I think the first small batch will probably be kits of pcbs and components for those who like to solder their own gear. And as pzs mentioned, the case and buttons would be 3d printed.

After that, it would be a matter how much demand exists to produce a “real” product in volume.

Kickstarter!!!

But i am down.

+1 for speaker!

Tiny Speakers!

These little guys put out more sound than I had expected - absolutely no bass, but anything in the mids to highs is definitely discernible.

oof! That GIF of the vibrating speaker looks extremely satisfying ![]()

Thanks for sharing your journey btw! This is awesome!

That is cool. How does it feel to use it? Maybe following this project a bit :).

following!

so cool.

The perfect “missing link” (“chainon manquant” in French but I don’t know if it’s translatable) between the user and the TM. Can’t wait to see it working. Real great and exciting work !

Really nice! Looking forward.

So it has a small battery + usb c to charge and program?

Thinking out loud…

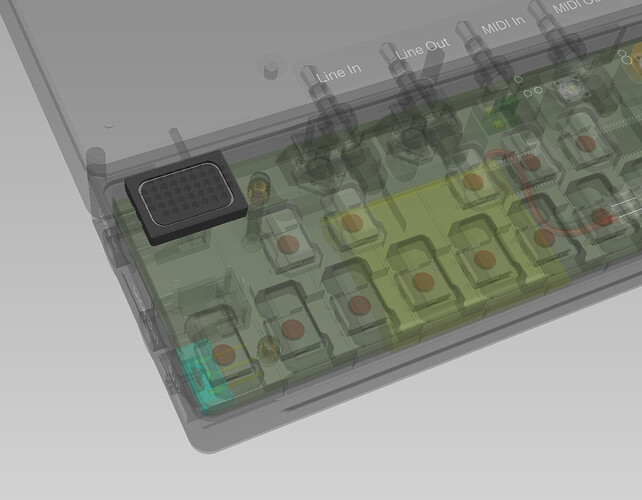

Do you have a plan for the people who will naturally try and hold the whole thing from the keyboard? seems like there will be a lot of pressure on the 3.5 plugs. There are 4 jacks, which is good.

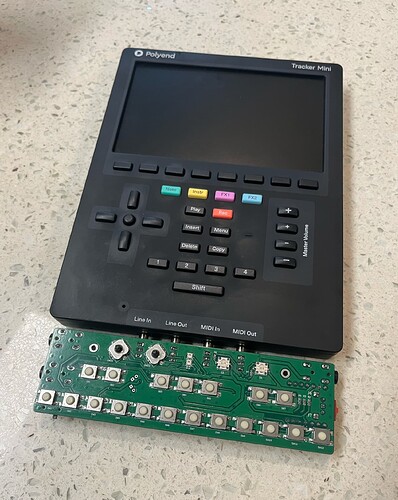

It’s pretty awesome to finally have a tiny keyboard attached to bottom without any extra cords n stuff. The key buttons are the lightest touch I could find (.5 newton force), so once the key caps are in place it should have a nice light feel.

It’s about 90% working right now. I’ll try to post up a video link soon.

The first lever is set to send midi cc3(micro tune) which acts like a pitch bend.

The second lever is set to send velocity levels, so it defaults to 72 and can up to 127 or down to 32 as needed.

Yes.

It runs off an ESP32 (Arduino compatible) with a small LiPo battery and is charged through the USBc port when plugged into power. The great thing about running c++ is that all the functions can be changed. The Levers can be set to anything we want and the Keys can be mapped to any scale we want.

The plan is to build an app to connect over Bluetooth LE for setting the functions.

I was planning on a back plate for support as you can see in some of the renders above, but after feeling how rigid it is with only the PCB, I believe once we add the case, it will be quite sturdy without it. It will come with a small “pry plate” lever to separate it from the TM. It requires a good amount of force to insert and remove all 4 plugs together.

Sounds great… Just thinking about lever arm and shear forces are different then a push pull ones. Also what makes it easier and harder to push and pull are manufacturing tolerances, which both sides will have.

In all cases, you are doing what I only babble about, so respect to this great project!